Design & Engineering

At Prabhu Laser, we offer engineering support services from the pre-prototype stage through production. Based on our knowledge of the materials, sheet metal fabrication and manufacturing technology, our engineers can make suggestions related to cost-effectiveness and manufacturability. Prabhu Laser talented engineering staff and programmers are trained in the use of the latest VPSS 3I AMADA software.

The engineering process can take simple customer supplied concept information and produce a professionally designed product that is ready for the manufacturing floor. Our Design & Engineering goal is to produce for our customers a product design that provides perfect function at an unbeatable price.

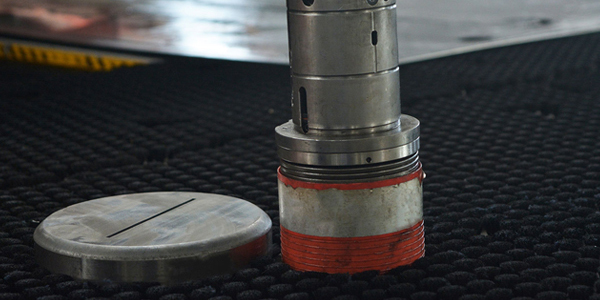

Laser Cutting

Laser cutting is a core competency at Prabhu Laser. We have been providing laser cutting services for over 16 years. Being able to control a broad range of laser parameters precisely helps transform a flat sheet of metal into numerous parts with a variety of characters without the need of extra tooling. By using our laser cutting services, you will have the precision parts quickly and cost-effectively.

Today Prabhu Laser has 4 AMADA Laser (4000W and 2500W) and capacity to handle large production laser cutting and small jobs as well.

Turret Punching

We have amplified and improved our sheet metal punching capabilities with the purchase of an Amada EM2510NT. This piece of equipment contributes to our success with manufacturers of elevators, Automobile, Construction equipment, enclosures, and many other sheet metal parts. It is built to be versatile in the operations it can perform and flexible in their ability to produce quality parts in batches of one. Punching CNC parts with this machine mean fast, flexible, high-quality production punching at a reduced cost per part.

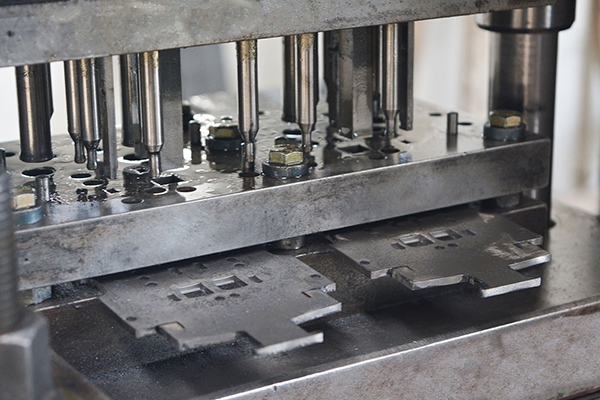

Metal Stamping

Prabhu Laser provides sheet metal stamping and custom metal fabrication .

From short run metal stamping to millions of pieces a year, Prabhu Laser has the facility, staff, management & equipment to handle your metal stamping needs!

Our extensive metal fabrication & sheet metal stamping capabilities include:

• 200T – 2nos (Mankoo)

• 100T – 1no Pneumatic Clutch (SEW)

• 100T – 2nos (Mankoo)

• 50T – 2nos (Mankoo)

• 50T – 2nos (Mankoo)

• 15T – 1no (Viswakala)

• 10T – 1no (Viswakala)

• Design & Creation of Special Precision Dies and Progressive Dies

Bending

Prabhu laser offers a wide breadth of metal bending services to its customers. Our technical precision allows us to continually ensure that all dimensional tolerances and accuracy in all angles are achieved to our customers’ exact specifications.

Prabhu Laser is well positioned to provide exceptional service and tight tolerances so that all sheet metal products meet or exceed our customers’ expectations

Our sheet metal forming equipment includes Amada CNC Press Brakes RG35, RG80, RGM2 1003 and FBD 2004 HM 1003.

Fabrication

When it comes to metal fabrication processes, whether carbon steel, stainless steel or aluminum, Prabhu Laser is the industry sheet metal fabrication leader. Our customers depend on us to produce quality products involving both metal bending, as well as custom metal fabrication. Prabhu Laser is well positioned to provide exceptional service and tight tolerances so that all sheet metal products meet or exceed our customers’ expectations. Our highly-skilled craftsmen, best-in-industry tolerances, a wide variety of available sheet metals, and great value give our customers the edge to beat their competition.

Prabhu Laser has all types of sheet metal equipment for efficient handling of your sheet metal parts. Our engineers will analyze your drawings & decide where the process starts: shear, punch or laser cut.

At Prabhu Laser, we offer full-service sheet metal, a custom metal fabrication which includes welding services for short and long production run jobs. Our extensive welding capabilities utilize welding in MIG and TIG. We are experienced in welding aluminum, MS steel, and stainless steel materials

The welding services at Prabhu Laser support our full-service fabrication process with capabilities including:

• Resistance Welding / Spot Welding

• Metal Inert Gas (MIG Welding) – This semi-automatic or automatic process uses a continuous wire feed 20 welding station.

• Tungsten Inert Gas (TIG Welding) – A manual welding process that is extremely precise, especially useful for welding thin materials. • Nut Welding, Stud Welding

Assembly

Prabhu laser is your custom metal fabrication company from start to finish! Our value-added assembly capabilities save you time, money and hassles.we manufacture value-added assemblies for elevator and automotive industries.

Prabhu laser is your custom metal fabrication company from start to finish! Our value-added assembly capabilities save you time, money and hassles.we manufacture value-added assemblies for elevator and automotive industries.

Powder Coating Process

We had setup a Powder coating plant with 9 Tank Pretreatment Process in 35,350Sqft area in our Sriperumbudur plant.

Oven Types and Products size:

Electrical Oven = Job size 11’ x 4.5’ x 4.5’

LPG Oven 1 = Job size 16’ x 4.5’ x 4.5’

LPG Oven 2 = Job size 7.5’ x 4.5’ x 4.5’

Electric cum LPG Oven = Job Size 12.5’x4.5’x4.5’

Packing & Fulfilment

Prabhu Laser offers shipping for local deliveries via 21feett,19feet and 17feet truck or small delivery truck.In addition to our in house delivery options ,we offers a host of shipping option. We have accounts with most major truck lines and will ship via customer preference.

At Prabhu Laser from start to finish, we aim to handle all fabrication jobs with the most professional and flawless manner possible.